Main features

● The Series Punching machine adopt rigid rotated key clutch with simple structure , easy operation and maintenance , helical gear transmission , smooth operation and low impact .

●J23-25 open inclinable punching machine , first changed from traditional sliding bearing to ball bearing with higher wear resistance , avoid generating big gear noise due to brass faster abrasion .

● J23 Series Open inclinable punching machine is unique in the industry with transmission brass gear .

● Redesigned machine body with higher strength , at the same time , completed with ball beading transmission ( small noise)

●J23-80 and above tonnage punching machine is in pneumatic dual-balance cylinder structure with low balance fluctuation , balancing slider and upper die weight , and avoid machine shaking caused by after-mentioned weight .

● Prevent gear backward force colliding and making noise , eliminating clearance between connecting rod and slider and reducing force component impact and abrasion .

● Avoid slider falling accidents due to brake failure or connect rod breadage .

Configuration

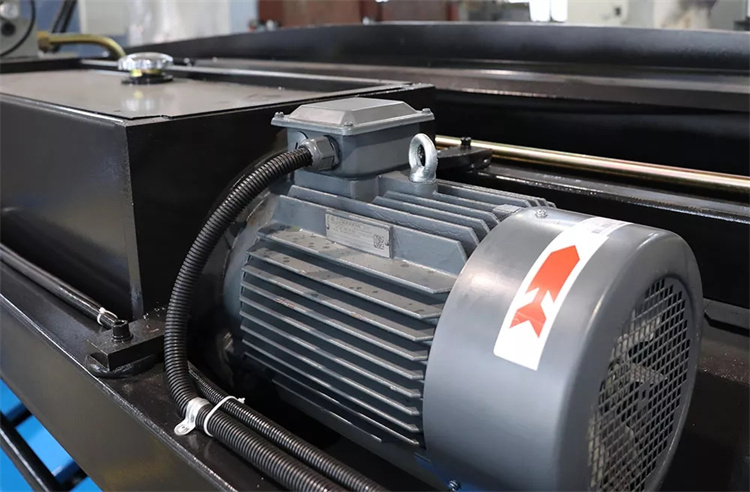

●Chinese high-performance motor

●France Schneider electric

●Safety standard (2006/42/EC )

●Left and right safety fence

●Open electric cabinet door to cut off power

●China pedal switch (Safety Grade 4 )

●Left and right safety fences line with CE Standard

● Safety relay monitors pedal switch , safety protection

विशेष विवरण

ना | तकनीकी पैमाने | इकाई | JB23-160T | |

1 | Norminal Pressure | के.एन. | 1600 | |

2 | Norminal Pressure stroke | मिमी | 10 | |

3 | स्लाइड स्ट्रोक | मिमी | 130 | |

4 | Max Closed Height | मिमी | 410 | |

5 | Die hight adjustment | मिमी | 80 | |

6 | Bolster size(F.B*L.R) | मिमी | 650*1100 | |

7 | machine outline size(L*W*H) | मिमी | 2000*1600*2900 | |

8 | इंजन की शक्ति | किलोवाट | 15 | |

9 | Motor speed | R/min | ||

10 | वज़न | KG | 12000 | |

Parts

1. Die Height Adjustment manually.

The height of the abrasive tool can be adjusted according to actual needs. Very convenient to use.